Background: Due to the rapid development of the power battery industry—driven by trends like the module-to-pack design evolution, a deeper understanding of application scenarios, and improved performance—as well as updates to related system standards, the 2015 version of the standard no longer meets current requirements and urgently needed revision.

Process & Outcome: The Sub-technical Committee on Electric Vehicles of the National Technical Committee of Auto Standardization initiated preliminary research in 2020. This culminated in the release of GB/T 31486-2024 “Performance Requirements and Test Methods for Power Batteries of Electric Vehicles” in September 2024. This new standard is set to take effect on April 1, 2025.

Replacing the 2015 version, the key technical changes in the 2024 standard include:

- The 2015 version targeted both modules and cells for testing, whereas the 2024 version specifies test requirements only for cells, eliminating test items for modules.

- Addition of requirements for high-temperature charge retention capacity, recovery capacity, and the allowable variation in energy efficiency.

- Revision of test subjects and environmental conditions, including new requirements for high/low-temperature test chambers.

I. Changes in Test Conditions

1.Test Environmental Conditions:

- The room temperature requirement has been tightened from 25±5°C to 25±2°C.

- A requirement for airspeed in the high/low-temperature test chamber has been added: ≤1.7 m/s, or the use of a test fixture compliant with Appendix A.

- Purpose of Change: To minimize the impact of ambient temperature on electrical performance.

2.Instrument Accuracy:

- Accuracy requirements for voltage, current, dimension, and mass measuring instruments now specify FS (Full Scale), thereby raising precision demands.

- To meet this, appropriately sized measuring instruments must be selected.

- Requirements for voltage, current, and temperature control deviation have also been introduced.

3.Increased Requirements for Data Logging Intervals:

- For tests without a specified interval, the data recording interval shall not exceed 100 seconds.

- For the room-temperature rate capacity test, the data recording interval shall not exceed 100 milliseconds.

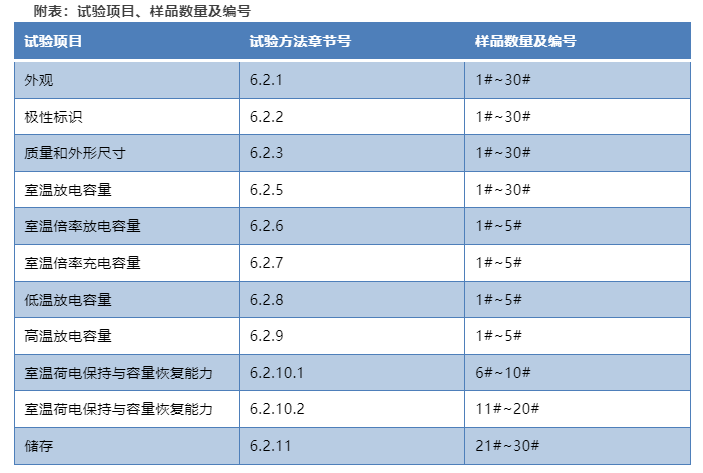

II. Test Items

- Elimination of Module-Level Testing: The updated standard no longer includes the concept of or tests for “modules.” All tests previously applicable to modules now apply to cells (battery cells)+. This change is driven by evolving battery structures, such as the emergence of CTP (Cell-to-Pack) and CT (Cell-to-Chassis) technologies.

- Removal of Vibration Test: Vibration testing, being a mechanical performance assessment, has been removed as it falls outside the scope of electrical performance evaluation.

- Differentiated Testing for High-Power vs. High-Energy Batteries:For electrical performance tests:

- High-power batteries shall use a 1I1 current for charge/discharge cycles.

- High-energy batteries shall use a 1I3 current for charge/discharge cycles.

III. Test Parameters

- The duration for the storage test has been extended from 28 days to 30 days.

- The temperature for High-Temperature Charge Retention and Capacity Recovery tests has been lowered from 55°C to 45°C, aligning with the revision logic for other high-temperature tests.

- The temperature for the High-Temperature Discharge Capacity test has been lowered from 55°C to 45°C, ensuring consistency with other high-temperature state tests.

IV. Test Requirements

1.Room-Temperature Rate Discharge Capacity:

- The requirement for high-energy batteries has been increased from no less than 90% to no less than 95% of initial capacity.

- The requirement for high-power batteries remains unchanged at no less than 80%.

2.Room-Temperature Rate Charge Capacity:

- The 2024 version allows charging according to the manufacturer’s specified charging strategy, provided the total charging time does not exceed 30 minutes. The previous maximum current limit of 400A has been removed.

- The performance requirement remains unchanged from the 2015 version: discharge capacity must be no less than 80% of the initial capacity.

3.High-Temperature Discharge Capacity:

- The test environment temperature has been adjusted to 45°C.

- The performance requirement has been tightened: discharge capacity must now be no less than 95% (increased from the previous 90%) of the initial capacity.

4.Room-Temperature Charge Retention and Capacity Recovery:Requirements have been tightened. Retention capacity must now be no less than 90%, and recovery capacity must be no less than 95% of the initial capacity.

5.Storage Test:The required recovery capacity has been increased from no less than 90% to no less than 95% of the initial capacity.

Post time: Jan-23-2026